ABOUT US

CORDIA PLUS has been present on the market since 2000. Dynamic development and extraordinary innovativeness have provided us with a stable position and reputation. We are constantly expanding the circle of customers, expansively entering new European markets with our offer, making the brand recognizable, associated with high quality products and comprehensive customer service.

Anodising plant is one of the departments in the company, in which we constantly invest and develop so as to be able to constantly improve the quality and efficiency of services.

Anodizing is also called eloxal process (electrolytic oxidation), a surface treatment of metals consisting in electrolytic formation of an oxide layer. Anodising is applied mainly to aluminium and its alloys. The process of anodising serves mainly:

- for anticorrosive and mechanical surface protection of elements,

- for visual purposes (colour-covering).

The advantage of our company is not only to provide a very good quality, but also short lead times and individual approach to each order.

We provide services regardless of the number of elements (starting from 1 piece).

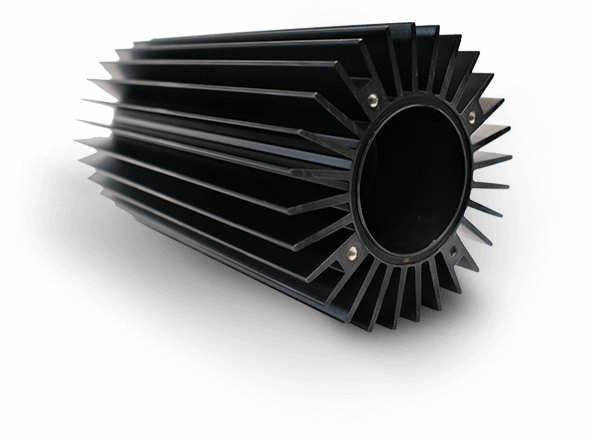

We specialize mainly in anodizing small and medium elements after processing, where the priority for the customer is, in addition to high quality, the lack of visible traces of the hanger (the so-called "traceless" anodizing).

OFFER

We offer the service of anodising aluminium details (both from our own material and from provided details) with a maximum length of up to 2.2 meters.

We specialize mainly in anodizing small and medium elements after processing, where the priority for the customer is, in addition to very good quality, the lack of visible traces of the hanger. (the so-called „traceless” anodizing).

The thickness of the oxide coating that we make is between 5 and 30 microns, depending on the customer’s requirements.

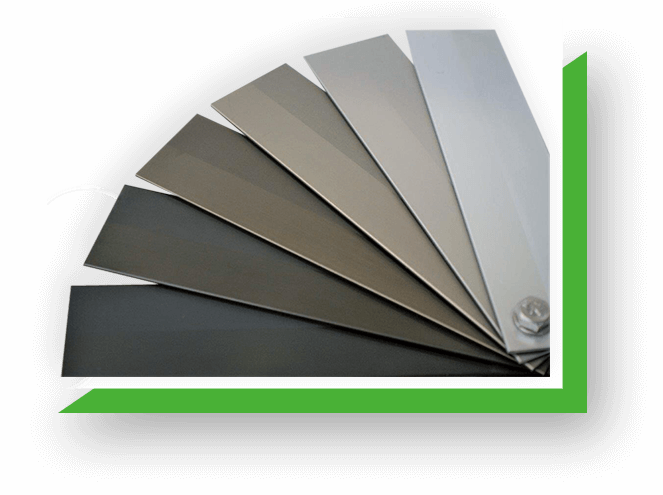

Palette of offered colours:

– natural anode C-0

– anode steel C-31

– anode champagne C-32

– brown anode C-34

– black anode C-35

After rendering the anodizing service, we perform an internal control of the packed profiles and prepare orders for transport.

We guarantee high quality of services, attractive, competitive prices and short lead times.

Glass blasting, otherwise sand blasting or satin finishing is a process of mechanical processing of aluminium surfaces. It is particularly recommended for the preparation of aluminium surfaces, aesthetic values of which are supposed to play an important role. During such treatment, the material is deprived of all impurities, i.e. rust and deposits.

Aesthetic values of the surface subjected to such treatment are also very important. As a result, the elements gain an aesthetic matte finish, and the surface has a fine structure.

PRICELIST

The price of the service depends on, among other things:

- The size of the surface of the work piece.

- The way of hanging the element,

- Quantities of elements

- Selected machining

- Type of packaging

- Condition of the surface area of the element supplied by the customer

We take an individual approach to each order, with due diligence in finding the optimal solution for the customer.

Before accepting a larger order, we always recommend a trial batch to confirm the quality, colour or e.g. the packaging method.

„CORDIA PLUS” spółka z ograniczoną odpowiedzialnością spółka komandytowa

32-640 Zator | ul. Władysława Grabskiego 10

Polska

NIP 551-23-03-829

REGON 852608644

KRS 0000551143

tel. +48 33 875 43 17

tel. +48 668 146 934